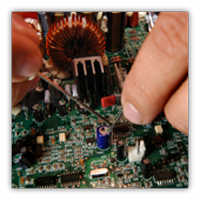

Printed Circuit Board Assembly

Creating printed circuit boards (PCBs) requires many steps, often beginning with bare boards that become the basis of prototypes in the initial stages of design. After defining the specifications of the project and laying out the PCBs, there may be additional prototyping or large-volume fabrication.

Via Technology offers full-scale PCB assembly services that go from bare PC boards to fabrication. When testing is complete and the product is ready for launch, we will assist you as needed in generating the necessary data, drawings and files to smoothly transition into production.

Flexible PCB Assembly

Depending on the product you're looking for and the type of business you operate in, our clients may choose to:

- Handle their own product manufacturing

- Have Via Technology take care of PCB production for them (fully managing production and test)

- Have Via Technology refer them to one of our qualified Contract Manufacturing partners for production services

Request Your PCB Assembly Quote Today

Whichever approach works best, Via Technology stands ready to assist our clients in each step of a product launch. With experienced designers and engineers on our staff, we can provide guidance through any concern or issue encountered along the way.

Contact our team today to discuss your project and receive a quote.

We serve clients all over the U.S. From right here in Buffalo, NY, all the way out to California and everywhere in between!

Bare Printed Circuit Boards and Flex Circuits

- Sourced through our ISO9001:2008 and ITAR registered suppliers

- Double sided or multilayer

Prototypes

- Bare PCB and component acquisition

Production Services

- ISO9001:2000 Certified

- SMT Stencil Acquisition & Printing

Test Services

- Support for third-party certification testing