Rigid Flex PCBs

Rigid flex CBs are a combination of flexible PCBs and rigid components. This allows the rigid flex PCB to have optimal strength and flexibility. It is composed of a flexible substrate layer joined to a rigid circuit board via pre-impregnated composite fibers known as pre-peg. Generally, the flexible portion is single sided, while the rigid component is often a multilayer PCB.

Like traditional rigid circuit boards, rigid flex PCBs have an FR4 base. Additionally, the rigid flex PCB has a flexible component of polyimide. The two are joined together through the lamination process after being fabricated separately.

What Are Rigid Flex PCBs Used For?

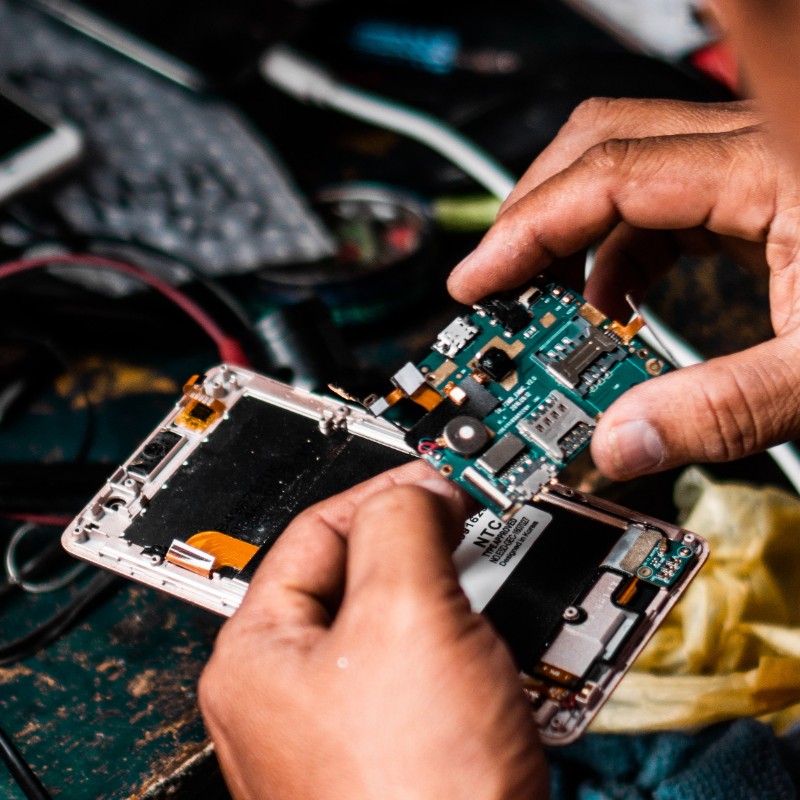

Rigid flex PCBs are ideal for pacemakers, cell phones and digital cameras. The rigid flex PCB takes up less space and weighs less than traditional rigid PCBs. It can also be a more cost-effective solution to some design issues, as the rigid sections provide sufficient area for component density, while the flexible portion maintains connections.

How Complex Are Rigid Flex PCBs?

Accurate planning and measuring is extremely important when designing rigid flex PCBs, and developing a prototype is particularly imperative for analysis purposes.

The manufacture of rigid flex PCBs is complicated by the fact that designs must take into account three planes, rather than just two. The 3D nature of the design is what allows the rigid flex PCB to twist, turn and fold. However, this also increases the complexity of the design as well as the design process itself.

The soldering and etching processes involved also complicate the process.

To get started with your rigid flex PCB project, contact Via Technology today!