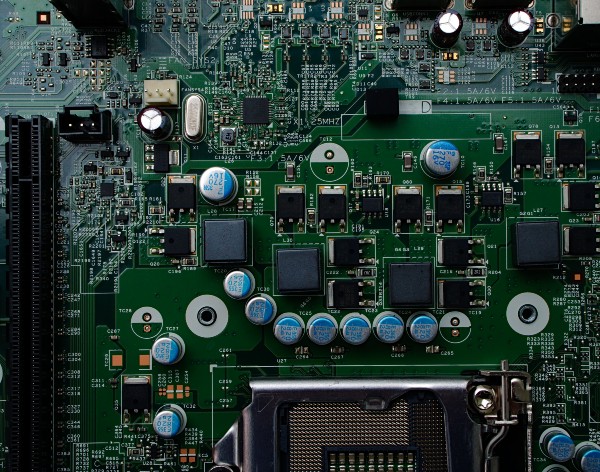

Metal Core PCBs

Design, Layout and Testing

Metal core PCBs utilize a metal material as their substrate instead of the traditional FR4 found in most other PCBs. The metals used are generally aluminum or copper, which are non-toxic and recyclable. Metal substrates are long-lasting and conduct better than epoxies.

Metal core PCBs are known by various names, including thermal PCBs, insulated metal PCBs, thermal clad PCBs, metal-clad PCBs and insulated metallic substrates (IMS).

What Are Metal Core PCBs Used For?

Metal core PCBs are an excellent choice for projects that require extra dimensional stability, or if there are concerns that the board will experience large mechanical loads or be exposed to high temperatures.

Metal core PCBs are also an excellent choice for high-power LED lighting applications and high-vibration applications, as the PCB's metal core helps reduce vibration levels.

How Complex are Metal Core PCBs?

When designing metal core PCBs, it is necessary to minimize the use of plated through-hole (PTH) components. Instead, surface mount technology should be utilized. Otherwise, the conductive component leads can be short. If it is necessary to use PTH, the metal must be isolated from the through-hole by drilling larger than necessary holes, which are then filled with non-conductive epoxy and then pressed.

While PCBs used for standard LEDs require thermal vias for heat dissipation, metal core PCBs do not since the metal core dissipates the generated heat. This speeds up manufacturing time, as the drilling process is minimal.

Have Metal Core PCBs Designed for Your Needs

The increasing demand for high-power PCBs with high component density makes thermal management more crucial than ever. Utilizing metal core PCBs can address this issue. However, good thermal management means considering factors such as the design, the enclosure and the environment, as well as the heat generated by the components themselves.

Our PCB designers will consider all these considerations right from project conception.